Fortunately, in 2023, the decline in utility model applications was interrupted: With 9,709 applications, there was a 2.5% increase in applications received by the DPMA compared to 2022. The increase was a result of the higher demand from abroad, especially from China. Just as patents, utility models protect technological inventions. Unlike patents, though, utility models are not examined for novelty and inventive step prior to registration. For this reason, utility model protection can be obtained more easily, faster and at lower cost than patent protection. This makes it attractive for many applicants.

There were rising application numbers in almost all technology fields. In the sector “Other fields”, applications declined with respect to furniture and games (-4.8%) and with respect to civil engineering (-3.2%). 75.1% of the utility model applications were filed via the electronic services of the DPMA, an increase of 1.7 percentage points compared to the previous year.

In 2023, a total of 9,709 utility model applications were received by the DPMA (2022: 9,470), representing an increase of 2.5%. The number of utility model applications split off from patent applications was 966. A splitting-off application means an independent utility model application for which the date of filing of an earlier patent application is claimed.

As with patents, the technology field “Electrical machinery, apparatus, energy (electrical engineering)”, with 1,056 applications, saw a particularly significant increase (+24.8%) in 2023. The continuing progress of digitisation most certainly drove up the application numbers. In the second strongest field of technology, “Transport”, 906 applications were filed. In the field of medical technology (“Instruments”), we saw a considerable 12.7% increase, too. Basically, it should be kept in mind that technical, chemical and biological processes can be patented, whereas utility model protection does not cover processes (manufacturing and working processes).

The Utility Model Unit entered a total of 8,325 utility models into the register. This means that 89.3% (previous year: 89.0%) of the concluded registration procedures handled in 2023 were successfully concluded for the applicants. 996 applications were not registered because of withdrawals of applications or refusals or for other reasons (2022: 1,083).

The term of protection was renewed for a total of 16,817 utility models (previous year: 17,632) after payment of the maintenance fee. The number of utility models which lapsed, for example because no request for renewal had been filed or due to the expiry of the maximum term of protection, increased by 2.8% to 11,590.

At the end of 2023, 67,016 valid utility models were registered at the DPMA (previous year: 70,254).

Utility model applications in 2023

Applications at the DPMA and PCT applications that have entered the national phase

1 According to WIPO IPC concordance table, available here.

Foreign applicants were as interested in German utility models as before. In 2023, the percentage of applications from abroad increased once again, from 41.7% (3,946 applications) in the previous year to 43.3% (4,200 applications). Compared to the previous year, there was again a sharp decline in the number of PCT applications in the national phase; the number of these applications fell by 13.0% to 355. 5,509 utility model applications came from Germany, which corresponds to 56.7% of all applications (previous year: 58.3%).

Foreign applications largely came from non-European countries; compared to the previous year, their number again increased significantly to 3,238 (2022: 2,936). The smaller share of foreign applications came from European countries (excluding Germany). The number of these applications decreased by 4.8 percentage points to a total of 962 in the year under review.

As in the past years, the People’s Republic of China held the top position with 1,558 applications (previous year: 1,159) and a proportion of 16.0% of all applications. Chinese companies use utility models to have many possible embodiments of a product protected and to ensure they have much room for the future development of the product. Despite a 20.7% decrease to 511 applications (5.3%), India once again took second place. It was followed by the United States with a proportion of 3.6%, just ahead of fourth-placed Taiwan with 343 applications (3.5%). Among the European countries, Switzerland and Austria led the ranking with 182 applications (1.9%) and 174 applications (1.8%), respectively.

| countries of origin | Applications | Percentage |

|---|---|---|

| Germany | 5,509 | 56.7 |

| China | 1,558 | 16.0 |

| India | 511 | 5.3 |

| United States | 352 | 3.6 |

| Taiwan | 343 | 3.5 |

| Switzerland | 182 | 1.9 |

| Austria | 174 | 1.8 |

| Republic of Korea | 134 | 1.4 |

| Italy | 121 | 1.2 |

| Japan | 89 | 0.9 |

| Others | 736 | 7.6 |

| Total | 9,709 | 100 |

In a comparison of the German Länder, North Rhine-Westphalia is also the clear leader in 2023 with 1,468 registrations (26.6% of all domestic registrations); Bavaria and Baden-Württemberg follow with 1,254 registrations (22.8%) and 1,003 registrations (18.2%), respectively. Looking at these data in relation to the size of the population of each German Länder, Baden-Württemberg and Bavaria top the list with nine applications per 100,000 inhabitants each, followed by North Rhine-Westphalia with eight applications.

If the cursor is moved over the chart, it shows the utility model applications in 2023 and the applications per 100,000 inhabitants as well as the change in percent per German Länder (residence or principal place of business of the applicant).

A split-off utility model provides supplementary protection during the period between the filing of the patent application and the grant of the patent. Many patent applicants use it as a low-cost and quickly effective measure in order to be able to effectively take action against the copying of their innovation. Upon registration of the split-off utility model, an invention enjoys full protection, irrespective of the course of the patent procedure. In the case of a split-off, the date of filing of the earlier patent application can also be claimed with respect to the (later) split-off utility model. Compared to the previous year, there was only a slight decline in split-off utility models; the percentage of split-off utility models was 9.9% of all applications (2022: 10.4%).

A major difference between a utility model and a patent is that a utility model is simply registered, without an examination of the protection requirements by the DPMA. For this reason, a utility model is considerably faster and cheaper to obtain than a patent, but it offers less legal security. Any third party may at any time file a request for the cancellation of a registered utility model. Such a request must be accompanied by a statement of reasons. To avoid a later cancellation of the utility model, the applicant can file an early search request with the DPMA. The patent examiners will then determine the state of the art that must be considered to evaluate the protectability of the subject matter of the utility model application.

The number of effective search requests received by the DPMA last year slightly decreased to 1,186 (previous year: 1,274), and 1,154 searches were concluded (previous year: 1,423).

Cancellation proceedings are an efficient instrument to subsequently clarify the protectability of an initially unexamined utility model. Compared to the previous year (72), the number of requests for cancellation increased again; in 2023, the DPMA received 84 new requests for cancellation.

A utility model can be cancelled upon request only. Anyone can file a cancellation request; neither the looming risk of an infringement dispute nor an economic interest is necessary, for instance. A fee of 300 euros is due upon filing of the request. The request for cancellation must contain a sufficient statement of reasons. The most frequent reason for cancellation is that the subject matter of the utility model cannot be protected. An invention can be protected if it is new compared to the state of the art and involves an inventive step. If a lack of protectability is submitted as the reason for cancellation, any conflicting prior art should be cited in the request for cancellation. Other reasons for cancellation that can be submitted are an inadmissible extension of the subject matter, usurpation or that the subject matter of the utility model has been protected on the basis of an earlier patent or utility model application.

Cancellation proceedings are bilateral proceedings in which the party making the request and the proprietor of the disputed utility model as the opponent are involved. The Utility Model Division decides on the request for cancellation. Its panel consists of three persons: a lawyer as the chairperson and two patent examiners responsible for the technical field in question as reporting and associate judges. As in civil cases, the losing party must usually bear the costs of the proceedings.

In most cases, a decision on the request for cancellation is based on oral proceedings. Oral proceedings take place in the offices of the DPMA in Munich. In the year under review, parties made hardly any use of the option to obtain a decision in written proceedings or, in the case of appropriate proceedings, of the option to file a request for participation (from Germany) using image and sound transmission.

In the year under review, a total of 88 proceedings were concluded.

150 years ago Melitta Bentz and the reinvention of coffee

Sometimes, simple ideas can pave the way for great stories. In 1908, with the Imperial Patent Office (Kaiserliches Patentamt) in Berlin, a utility model was filed which was to become important in many respects. First, the applicant was one of the first women to have their own inventions protected. Second, the invention became such a success that it can be found in nearly every household today and that it laid the foundations for a company that is flourishing even a century later.

Melitta and Hugo Bentz

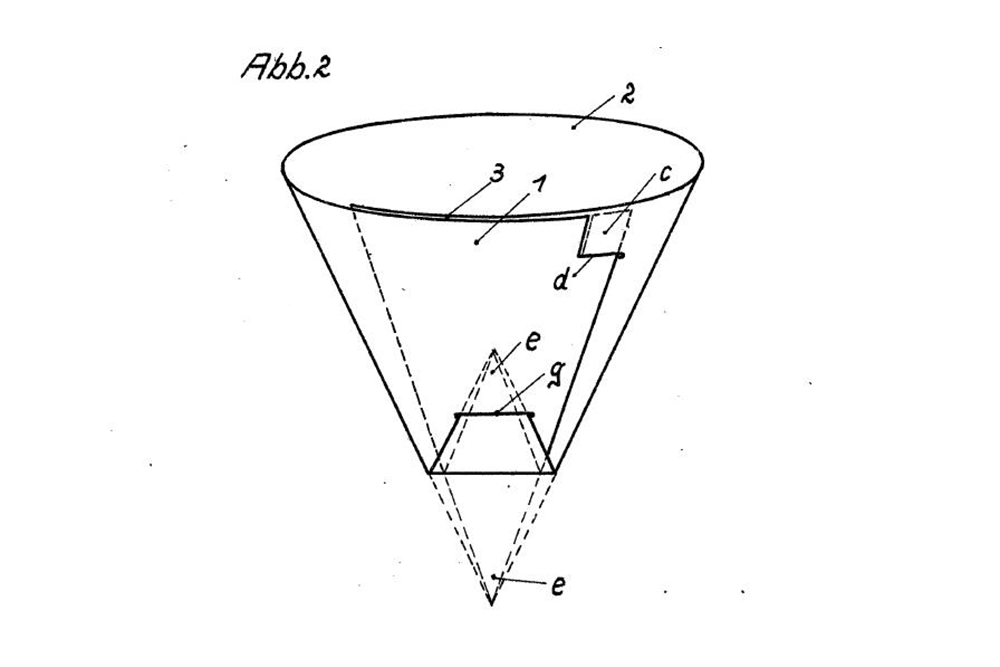

Prototype filter of 1908

Enhanced filter of 1910

Melitta coffee filter: drawing from patent specification DE 653796A (1937)

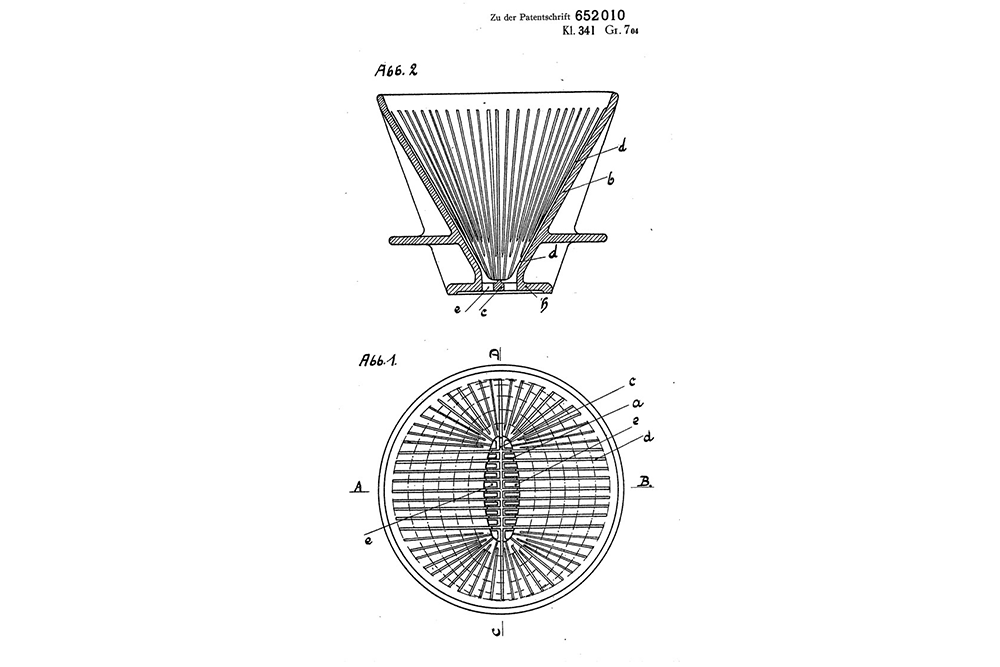

Shape of the filter as used until now according to DE652010 of 1936

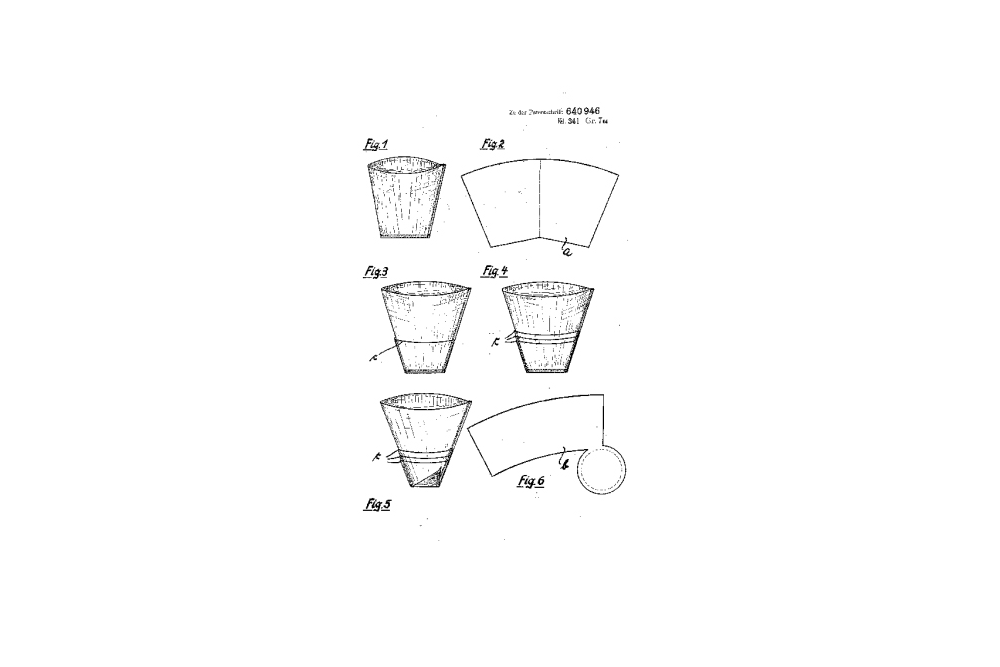

Filter paper according to patent specification DE640946 of 1935

Melitta Bentz

Melitta, 1142721-DE

Amalie Auguste Melitta Liebscher was born as the daughter of a bookseller in Dresden 150 years ago, that is on 31 January 1873. She married the salesman Emil Hugo Bentz and had two sons with him: Willy and Horst. As every housewife, Melitta Bentz was constantly looking for new solutions to the various challenges of everyday life. In principle, this is no different in a company — and Melitta's household was to become a company very soon.

Ingeniously simple — simply ingenious

Melitta Bentz was looking for new ways to brew better coffee. Until then, in order to brew coffee, you would pour hot water over ground coffee beans and wait until the powder grounded, to some degree, at the bottom of the pot (that is why coffeepots have their nozzle at the top – unlike teapots, in which the leaves float at the surface). Alternatively, there was the possibility of sieving the mixture. However, this rarely resulted in clean coffee, as the holes in the sieve were usually either too small and blocked or too large so that most of the grounds floated back into the cup. The coffee was often only lukewarm after this procedure. And the coffee grounds left an unpleasant aftertaste.

Melitta Bentz experimented in her kitchen using a roughly perforated brass cup as a sieve. Then she had the idea of inserting an additional filter into the cup and looked for a suitable material, which she found in her son's exercise book. She took a sheet of blotting paper, cut it to size and placed it in the cup. This simple but ingenious idea revolutionised coffee preparation and paved the way for a company that is still successful today.

Melitta Bentz continued to work on optimising her invention for which she filed a utility model application with the Imperial Patent Office on 20 June 1908: “Coffee filter with curved bottom perforated by slanting extraction holes”. The IP right was registered on 8 July 1908 on page 1145 of the Patent Gazette of the Imperial Patent Office in Berlin (unfortunately this and other utility model documents of Melitta were lost during the Second World War).

Building up a family business

It was at an early stage of her career that Melitta Bentz became aware of her invention’s commercial potential and took first steps towards bringing the new filter to market. Together with her husband, who soon gave up his job in favour of their joint business idea, she founded a company. The new company was entered in the commercial register on 15 December 1908. The headquarters of this “commercial agency and commission business” with the title “M. Bentz, Marschallstraße 31” and a registered starting capital of 72 pennies initially was a room in the Bentz family's Dresden flat.

Melitta Bentz had the first 50 filter bodies manufactured in a metal goods factory in Westphalia, while the first filter paper was supplied by a paper factory in Saxony. The married couple also proved to be highly inventive when it came to bringing their products to market. Hugo Bentz started canvassing the local shops and presenting their invention. Then he made product demonstrations with the filter in the shop windows. There had never been anything like this before, so this created quite a furore. Later, specially hired “demonstration ladies” were recruited for this task. Meanwhile, Melitta Bentz practically invented structured sales and demonstrated her filter at private coffee parties — a sales model that is still successfully used by some companies today.

The two sons of Melitta and Huge Bentz were also employed in the young family business. Using a handcart, they delivered the goods to the first customers. In 1909, the filters were presented at the Leipzig trade fair. With over 1,200 units sold, they were a great success. In 1910, the “filtering apparatus” was awarded diverse medals at the international hygiene exhibition in Dresden.

The married couple continuously expanded their small company and had some trade marks registered in order to protect it. In 1911, they had the word mark “Melitta” registered for “coffee filters” (Ref. 156 696/21, filed on 13 September 1911). In 1913, they had a homonymous word mark registered for “household and kitchen appliances, filter paper, cooking and heating appliances” (Ref. 180 819/07, filed on 27 March 1913). Both are still valid today.

Leading a company in difficult times

The First World War set Melitta back considerably. Coffee imports came to a standstill, paper became scarce and Melitta's husband and son had to go to the front. Almost single-handedly, she got the small company through the war years and the troubled times that followed. In 1923, her eldest son Willy became co-owner and boosted sales. The upswing of the company, now called "Bentz & Sohn OHG", began.

In 1925, Melitta introduced the iconic red and green filter paper packs in order to provide protection against imitators and had this colour combination, which is still common today, protected with a trade mark. In 1929, the company ran out of space in Dresden and moved to Minden in Westphalia, where it is still based today. It was renamed “Melitta-Werke AG” in 1932.

The filter takes on its shape known today

Between 1932 and 1937, the Bentz family’s company further developed the metal round filter into a quick filter made of porcelain. Initially, flat filter paper was used, which was pressed into the correct shape using an aluminium indenter. In 1936, the porcelain filter was given a new shape. From then on, the base was oval and tapered, as can be seen from patent specification DE 652010. The company also developed matching filter bags that adapted better to the shape of the filter vessel, as the filter paper rested on the ribs of the inner wall. The company has practically retained this shape of the filter and the filter bags to this day. The filter bag was patented with the number DE 640946.

Over time, the family business developed into a very successful and innovative group of companies with hundreds of patents registered worldwide. In 1962, for example, Melitta was the first supplier to launch ground coffee in vacuum packaging on the German market and in 1965, the company group presented one of the first electric coffee machines.

Melitta Bentz died on 29 June 1950 in Holzhausen near Minden. Her company once founded with only a few pennies of capital with its headquarters in a living room now produces around 50 million coffee filters per day. This is probably due to the fact that despite the current trend towards coffee pads and capsules, the classic filter coffee is still very popular (but Melitta now also caters for fans of fully automatic machines and pads). The group, which now comprises several dozen companies and thousands of employees, is currently managed by the fourth generation of the Melitta Bentz family.